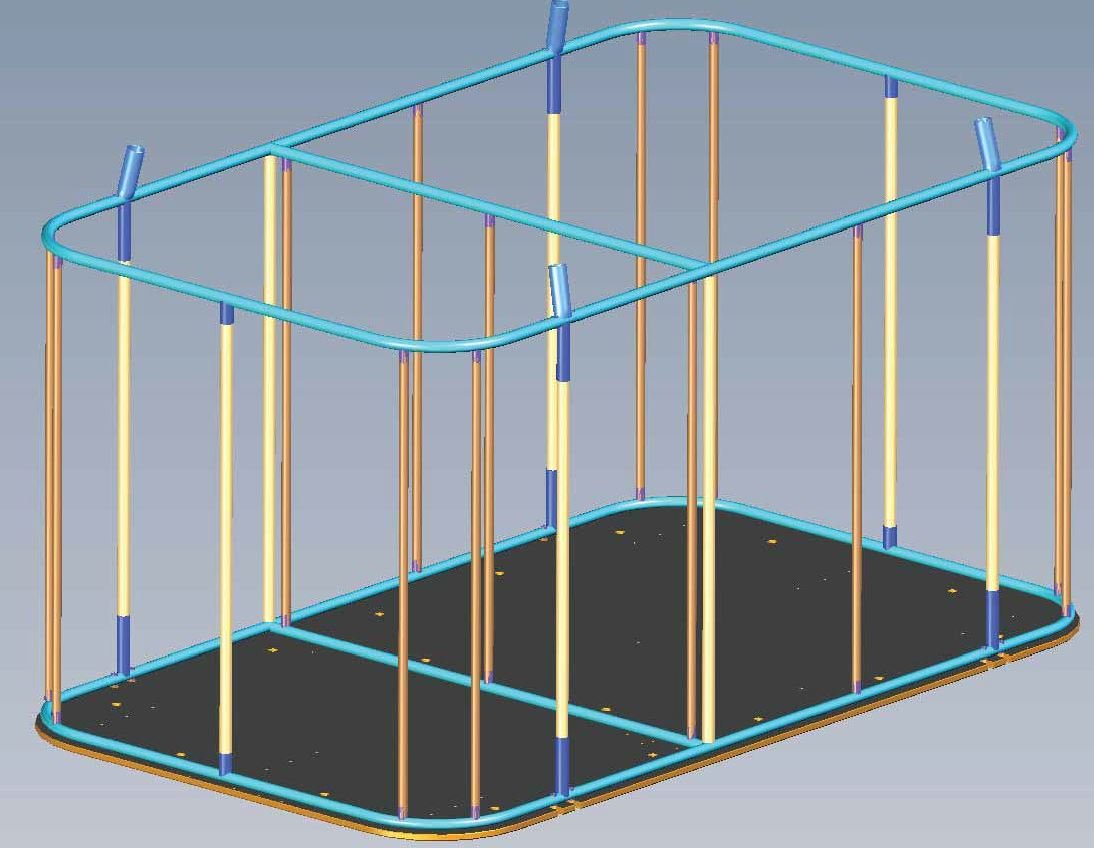

The major critical items in the basket are the steel cables that run from one karabiner, under the basket, and up the other side of the basket to the karabiner on the other side, crossing each other on the underside of the basket. These wires carry the weight of the basket and all its contents. Other important parts are the skids on the underside of the floor because they spread the weight of the basket and its contents over the entire bottom of the basket. The steel frames do not contibute to the elasticity of the basket but they do help to retain its rigidity.

Both the lower right hand flying wires on the envelope and the lower right hand basket wire are identified by red rubber covers over their swaged ends. Provided these wires are connected together and the other wires attached in the right order then the balloon will have been set up correctly.

Cylinders are held in the basket by cylinder straps, two horizontal straps to each cylinder. Straps from any balloon manufacturer may be used but they must be made from synthetic materials and be undamaged. Home made straps and leather straps may not be used.

Please note: Unlikely the other manufacturers, in our balloons we do not allow to tie the cylinders with leather straps. This is strongly a safety reason when the leather is difficult to untie and loose to take the cylinder out quickly in case of emergency.